1.Single-Story House

Rapid Deployment | Plug-and-Play Simplicity

Ideal for remote site offices or emergency clinics. Bolt-together assembly enables 24hr readiness. Standard 1K-12K widths (1820mm/module) with optional thermal insulation. Roof slope optimizes rainwater runoff.

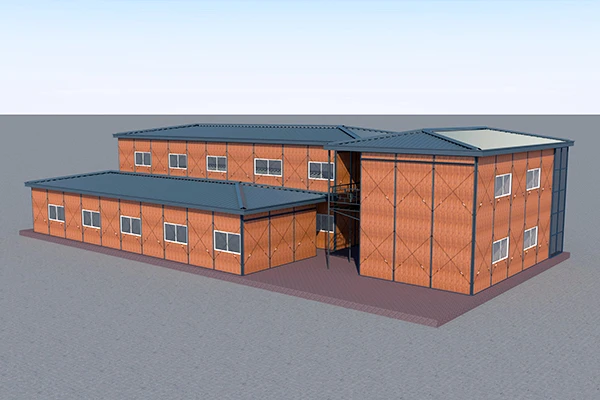

2.Multi-Story Houses

Vertical Expansion | High-Density Solutions

Stackable steel frames create 2-3 story worker camps or urban pop-up hotels. Interlocking staircases and reinforced floors (150kg/m² load) ensure safety. Wind-resistant (Grade 8+) for coastal/desert heights.

3.Combined Houses

Hybrid Functionality | Custom Workflows

Merge offices, dormitories, and storage in one complex. Example: 6K office + 4K dorm + 2K sanitation pod. Pre-wired utilities and modular partitions enable seamless integration.

4.Portable Houses with Bathrooms

Pre-Plumbed Sanitation | Off-Grid Capable

Integrated greywater systems and instant hot water. Fiberglass-reinforced bathroom pods slot into 2K modules. Critical for mining camps, event venues, or disaster relief.

5.Partitioned Houses

Adaptable Spaces | Acoustic Control

Soundproof movable walls (50dB reduction) create private offices, medical bays, or labs. Reconfigure layouts in hours without structural changes.

6.Environmentally Friendly House

Net-Zero Ready | Circular Design

Solar panel roofs, non-VOC insulation (rock wool/PU), and rainwater harvesting. 90%+ recyclable materials align with LEED certification.

7.High-Strength Houses

Industrial-Grade Resilience | Over-Engineered

Galvanized steel frames + cross-bracing for seismic zones. 300kg/m² floors support machinery. Used as on-site workshops or equipment shelters.