Assemble Container House: A Field Note on What’s Working in Off‑Site Builds

If you’ve watched construction schedules slip while budgets balloon, you’ve probably peeked at

modular building solutions more than once. I have too. And the assemble container111 house coming out of Fanxiang Village, Taoyuan Town, Wujiang District, Suzhou City, China, has been on my radar for good reasons: fast set-up, predictable quality, and—surprisingly—pretty decent acoustic comfort, according to a few site managers I trust.

Industry trend check: demand is pivoting from ad-hoc site cabins to stackable, code-conscious modules with real MEP integration. Lead times are shrinking to 4–10 weeks, depending on finish level. In practice, I’m seeing hybrid projects—core on-site, wings delivered as modular building solutions—to hedge risk and keep cranes moving.

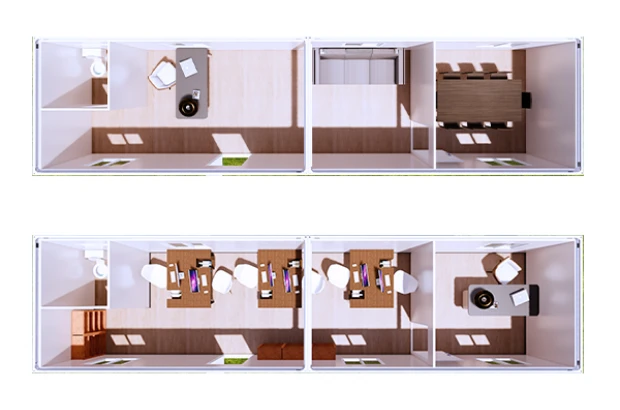

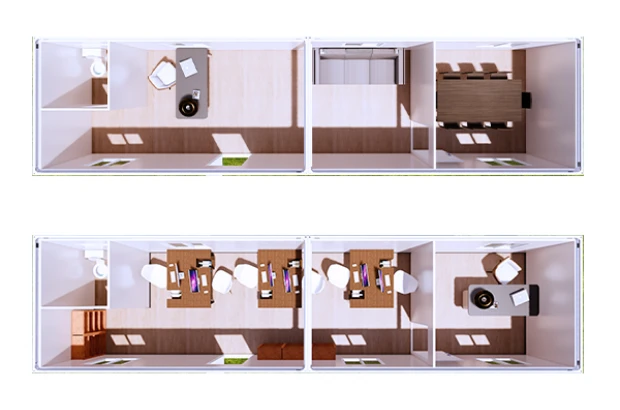

Product Snapshot: assemble container111 house

| Parameter |

Spec (≈ values; real-world use may vary) |

| Module size |

≈ 3.0m x 6.0–12.0m x 2.8–3.2m H, stackable up to 3–4 stories (site/soil dependent) |

| Structural frame |

Q235B/Q345B steel, welded & galvanized; EN 1090-compliant fabrication |

| Envelope |

50–100mm PU/EPS/Rockwool sandwich panels; U-value ≈ 0.35–0.45 W/m²·K |

| Flooring |

Steel joists + cement board/OSB + vinyl/laminate; live load ≈ 2.0–3.0 kN/m² |

| Fire & safety |

Rockwool option to meet ASTM E119/EN 13501; smoke/egress to IBC/GB codes |

| Wind/Seismic |

Wind ≈ 0.5–0.7 kPa; seismic per GB 50011 Zone ≤ 8 (project-engineered) |

| Service life |

≈ 25–50 years with proper maintenance |

Process & Quality Flow (short version)

- Materials: certified structural steel, factory-cut panels, galvanized fasteners, low-VOC finishes.

- Methods: CNC cutting, robotic welding where applicable, controlled curing; MEP pre-fit and pressure tests.

- Testing: weld NDT (UT/MT), insulation R-value sampling, door/window air leakage (ASTM E283), fire assemblies by rating; dimensional QC ±3mm.

- Certs: ISO 9001 QA system; EN 1090 factory control; IBC-aligned engineering packs; optional CE/UL-listed components.

Where it fits

Worker housing, pop-up classrooms, remote clinics, retail kiosks, site offices, disaster relief. Honestly, the speed is the hook; the tidy capex is the clincher. Many customers say the “plug-and-live” utility routing saved them weeks.

Vendor snapshot (what I’m seeing lately)

| Vendor |

Lead time |

Customization |

Certs |

Price/m² (≈) |

| ZN-House (Suzhou) |

4–8 weeks |

High: structure, MEP, facades |

ISO 9001, EN 1090 |

$260–$420 |

| Regional Fabricator A |

6–10 weeks |

Medium |

ISO 9001 |

$300–$500 |

| Import Reseller B |

Stock/variable |

Low |

Mixed |

$240–$380 |

Field notes and mini case studies

- Coastal worker camp (48 beds): 16 modules, installed in 9 days; blower-door spot checks showed ≈ 2.8–3.5 ACH50—better than expected for this class.

- Rural clinic (6 modules): rockwool panels, STC ≈ 35–38 dB; energy logs hinted at ~8–12% HVAC savings vs. a light-steel site build.

Customization tips

Ask for pre-plumbed wet walls, raised floors for cable runs, and exterior cladding brackets if you want a non-industrial look. For wind zones, request stamped calcs and hold-down details. If you’re pricing modular building solutions, compare fire assemblies by tested rating, not brochure wording—saves grief later.

Testing & standards (what to request)

- Weld NDT reports; mill certs for steel.

- ASTM E119/EN 13501 fire results for wall/roof assemblies.

- IBC/GB structural calculations with load paths and connections.

- Factory QA records under ISO 9001; traceability log.

Bottom line: for fast, repeatable delivery, the assemble container111 house format is a practical entry point into modular building solutions—and, to be honest, a sane way to de-risk schedules without overcommitting to a single procurement path.

- ISO 9001:2015 Quality Management Systems

- International Building Code (IBC 2021)

- ASTM E119 Fire Tests of Building Construction

- EN 1090-1 Execution of Steel Structures

- GB 50011 Seismic Design of Buildings