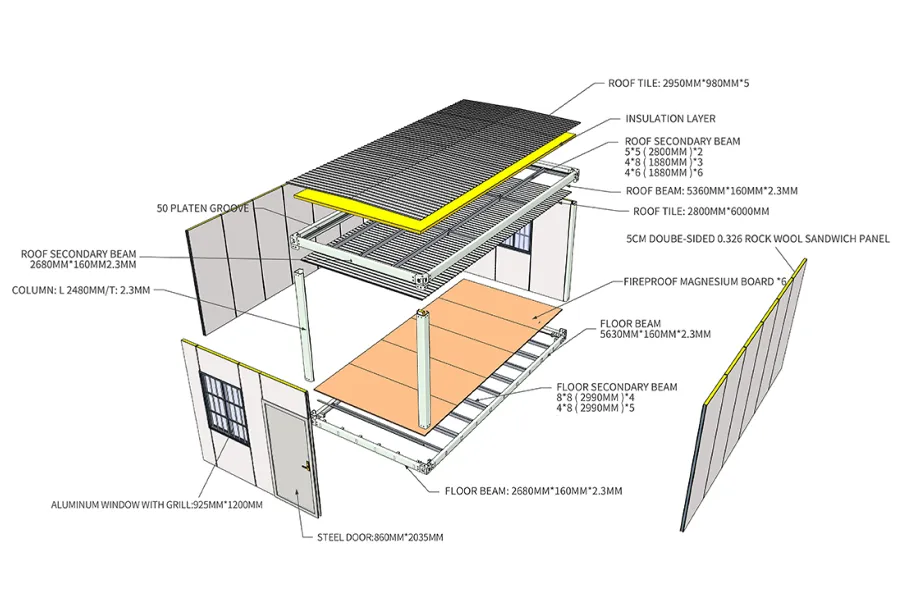

| Structural Components |

Anti-rust galvanized steel frames,Corten steel,galvanized fasteners,waterproof sandwich panels,tempered glass |

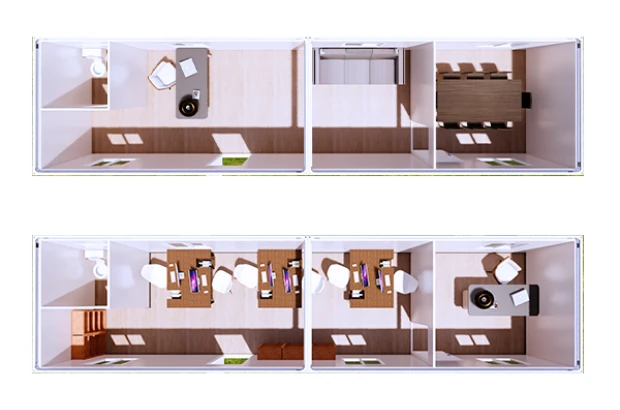

| Functional Components |

Modular sizes(10㎡to 60㎡per unit),customizable layouts,horizontal/vertical combinations,custom exterior/interior finishes |

| Exterior Finishes |

Rust-resistant metal carved panels,thermal-insulated rock,glass curtain walls |

| Interior Finishes |

Scandinavian wood paneling,industrial concrete flooring,bamboo accents |

| Energy&Sustainability |

Solar panels,underfloor heating,rainwater collection,greywater recycling,low-VOC paints |

| Smart Technology |

Remote control of heating,security cameras,door locks via smartphone app |

| Assembly Process |

Bolt-and-nut connections,80%customization(electrical wiring,plumbing,finishes)done in ISO-certified factory |

| Durability&Adaptability |

Rust resistance,corrosion protection,quick installation,adaptable for residential,commercial,disaster relief uses |