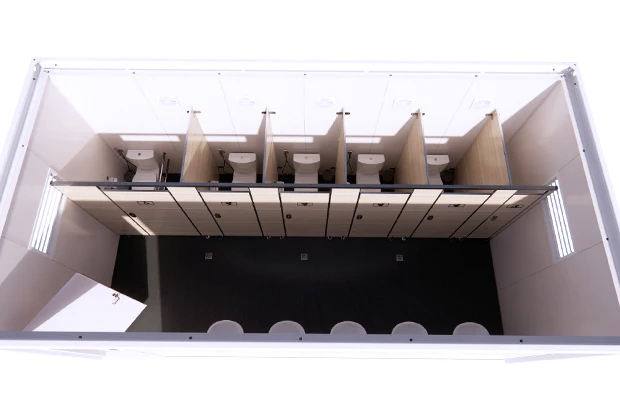

Best practices for installing an assemble container toilet include selecting a flat, level site, using the

right tools

(a cordless drill speeds the job), and working with an assistant for safety and efficiency. Ensure waste

collection and

disposal access, confirm local permits, and test water and electrical connections before handover. For

remote locations,

choose units with internal tanks and off-grid power options so the assemble container toilet functions

independently.

Maintenance keeps the assemble container toilet hygienic and ready for heavy use. Regular tasks include

emptying waste

tanks, cleaning surfaces, checking seals and door hardware, and restocking consumables like toilet paper

and hand

sanitizer. Insulation and heated piping are recommended for cold regions to prevent freezing. Suppliers

typically

provide spare-part kits, spec sheets, and installation videos to simplify upkeep and minimize service

interruptions.

Avoid common assembly mistakes by not over-tightening bolts, ensuring proper waste container alignment, and

confirming

ventilation is installed. With proper planning—tools, helpers, permits, and a level site—setting up an

assemble

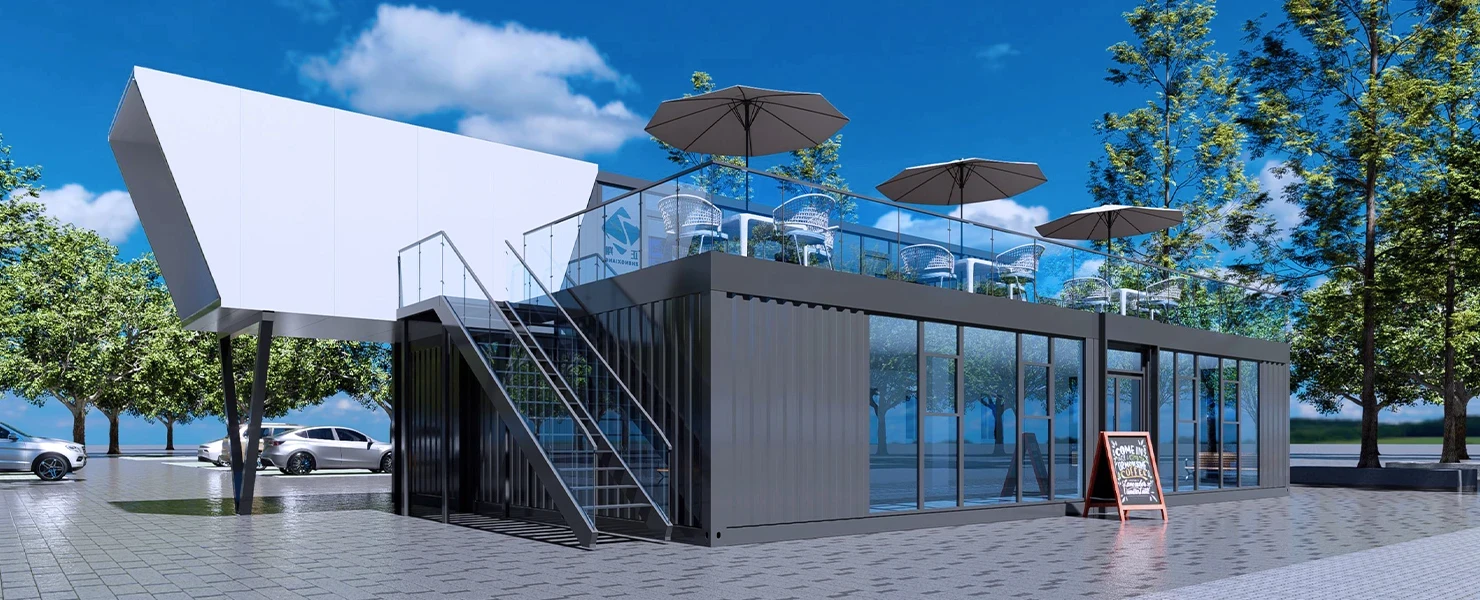

container toilet is fast and trouble-free. For event managers, construction supervisors, and relief

coordinators, the

assemble container toilet is a versatile, economical sanitation solution that scales with project needs.

Contact us to request a quote, or schedule an on-site demo of the assemble container toilet. Choose smart,

sustainable

sanitation that fits your project needs.